“Layton Consulting Fenestration Nerds” By Tyler Henderson: Understanding Spacer Modeling: A Simplified Approach for Reliable NFRC Thermal Simulations.

When I work with manufacturers and engineers on NFRC thermal simulations, one question comes up again and again:

“Do I really need to model every tiny detail of the spacer?”

As someone who builds these simulations every day, I’ve seen firsthand how much time and effort goes into preparing detailed spacer geometries. Manufacturers often provide complex CAD files with foils, coatings, and multilayer materials which are difficult (if not impossible) to accurately capture in THERM models.

This led me to explore a simple but important question:

Can we represent spacers with a two-box model?

At Layton Consulting, we recently evaluated a streamlined “two-box” spacer model to see whether it could stand in for detailed spacer geometry while still producing NFRC-compliant results. The idea isn’t new. It’s based on methodology from ift-Rosenheim, and is frequently used across Europe, but it hasn’t been widely adopted in North America.

Our goal was to test it and ask: Is this approach reliable enough for NFRC simulations?

What We Tested

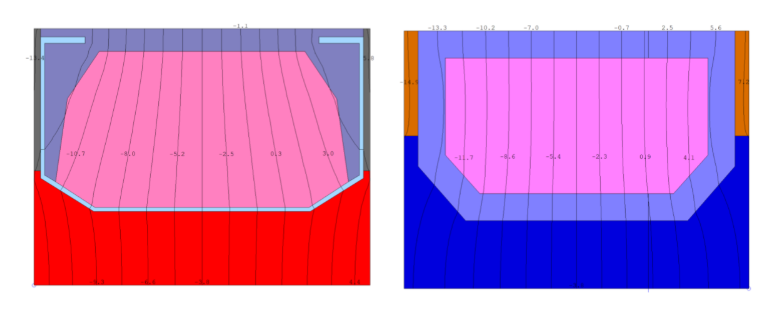

I looked at four common warm-edge spacers used across the industry:

· Chromatech Ultra S

· Multitech G

· SWISSPACER

· Technoform TGI

As well as one generic single seal aluminum spacer.

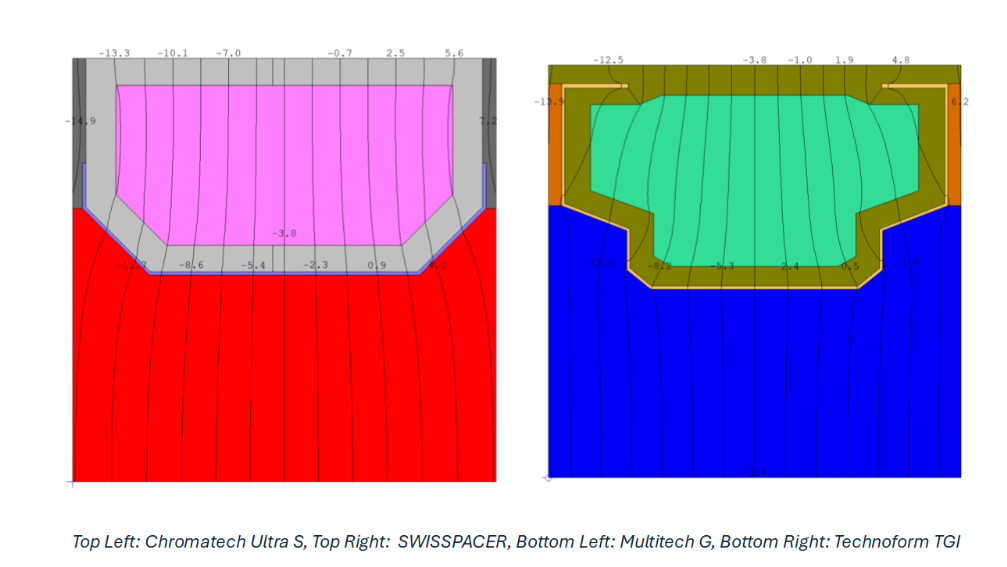

For each spacer, I created:

1. A detailed THERM model using manufacturer geometry

2. A simplified two-box model that mimics the heat transfer of the spacer without the fine detail

Then I calibrated the simplified model, so it matched the thermal performance of the detailed version.

Finally, I placed both versions into a full NFRC window simulation to compare product-level results such as:

· Whole-product U-Factor

· Condensation Index

What We Found

The outcome was clear:

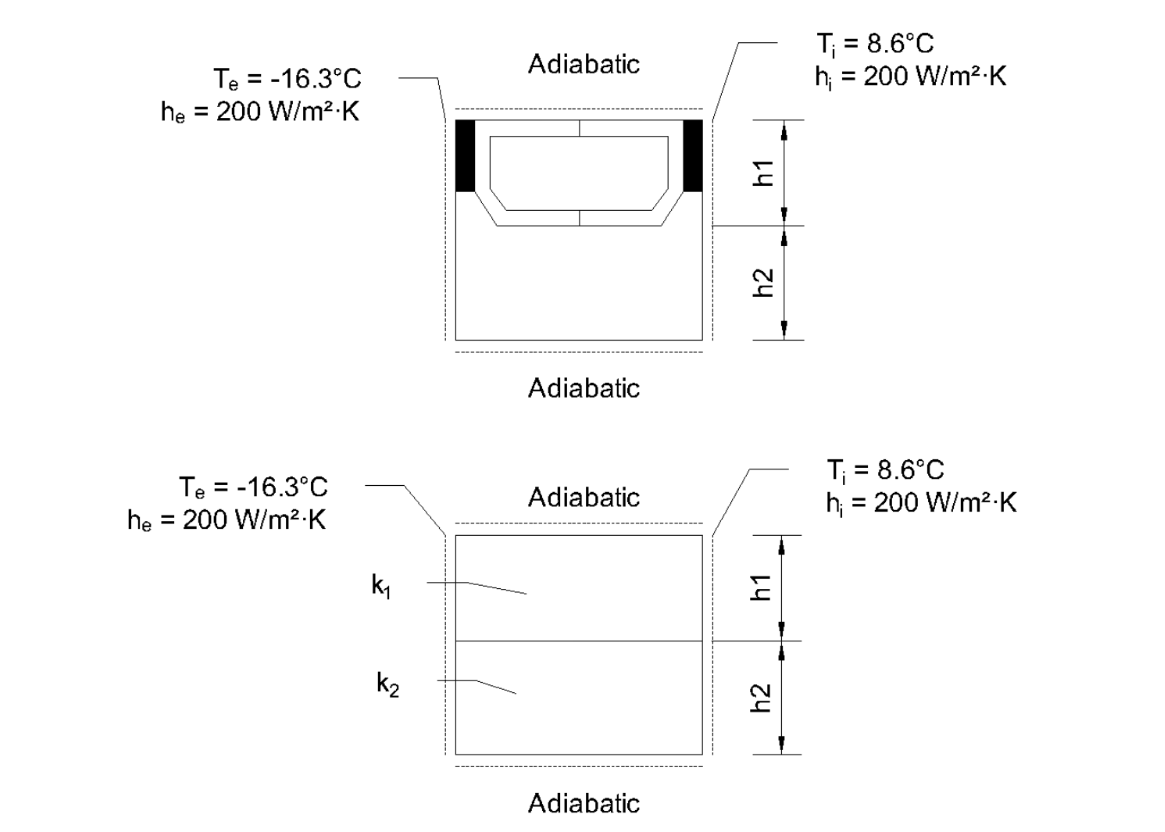

The two-box spacer models produced virtually identical NFRC results.

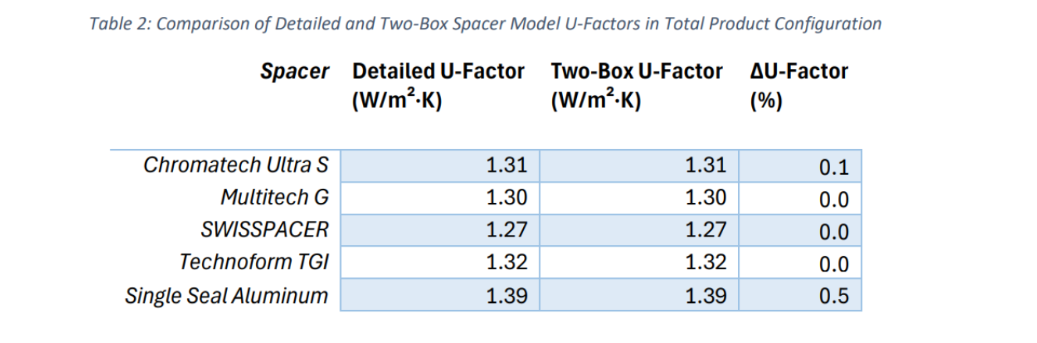

Differences in U-Factor and condensation indices were typically 0.0–0.5%, which is negligible and well within standard simulation tolerance.

Even in full product simulations, the simplified models matched the detailed versions with no meaningful deviation.

In other words:

· The simplified spacer models were just as accurate

· The final window performance stayed the same

· Simulation effort was significantly reduced

For simulation labs and consultants who run large numbers of simulations, this could represent real savings in time, cost, and modeling complexity.

Why This Matters for You

If you're involved in product design, certification, or performance testing, simplified spacer models could offer several benefits:

· Faster turnaround times for NFRC simulations

· Less modeling error, since detailed CAD translation is no longer needed

· Consistent spacer representation across product lines

· Reduced engineering labor, especially during early product development

And because the two-box models still reproduce the detailed performance, manufacturers don’t lose accuracy, which means confidence in the results stays high.

Looking Ahead

This work raises some interesting industry questions:

· Should NFRC consider allowing simplified spacer models?

· Could the industry establish a common library of verified two-box spacer models?

· How much engineering time could be saved annually if spacer modeling were standardized?

· Would labs and manufacturers support this shift if it meant faster certification workflows?

We see real potential here, not just for improving simulation efficiency, but for helping manufacturers bring products to market faster without compromising compliance or performance.

Want to Learn More?

If this topic interests you, I’d love to hear your thoughts:

· Have you struggled with spacer modeling in NFRC workflows?

· Would a simplified modeling approach help your team?

· What barriers do you see in adopting a methodology like this?

For anyone who wants a deeper look at the full methodology, calibration process, and validation results, you can read the complete technical report here: Evaluation of Two-Box Spacer Models for Accurate NFRC Thermal Simulations